We offer qualitative and maintenance free

range of Spring Operated Cable Reeling Drums. The spring-powered drums

are suitable for both A.C and D.C. Applications and are modified by

adding springs to the machines in order to attain the required tension &

accommodate the total length of cables. These are simple to mount and

can be mounted on the structure with the help of supporting flange.

Moreover, the springs used in these reels are contrived from the

highest quality materials and are of clock spring type.

Call Us : 08046054485

HIGH PERFORMANCE Cable Reeling Drums

Cable Reeling Drums

We are manufacturer and exporter of Cable Reeling

Drums.

Spring Operated CRD

ORTON make spring operated cable reeling

drums are powered with springs and has an automatic rewind feature which

provides an extremely simple way of supplying power to machines such as

cranes and hoists. These spring cable reeling drums are used for both AC

and DC applications. These reels recovers and store the cable in

multiple layer son the drum.

Standard reels are supplied for the cable fed in the clockwise direction, when viewed from the slipring side. The same can be provided for anticlockwise feed of cable also. These reels are extremely simple to mount, and can be mounted on the structure with the help of a supporting flange - If no suitable structure is available, then Unbalanced Vibrator Motor a bracket can be connected to the flange and this can be fixed to the floor or tray etc.

The springs used in these reels are manufactured from the highest quality materials and are of clock spring type. A wide range of characteristics can be obtained by assembling these springs singly or in series or in parallel.

All the power sliprings are designed for 600V AC operating voltage.

Spring operated cable reeling drums can also be supplied with geared rotary limit Switch arrangement.

ORTON have a complete range of motor driven torque controller cable

reeling drums. The reels shown in this catalogue are direct reeling

units where the cable compartment is mounted directly on the torque

controller. For those applications where the length and weight of the

cable is in excess of the design capability of the direct reeling units,

we have the indirect driven torque controller reels. With these reels

the torque controller unit powers the reel compartment through a

suitably selected transmission system. These types of cable reels are a

reliable, low cost solution for reeling long lengths of cable. These

drums are available for a complete range of cable lengths from 30 to 500

meters, for voltage up to 11000 V. These spring operated cable reeling

drums are easily installed, have an absolute minimum maintenance

requirement and are virtually unaffected by extremes of temperature and

environment. These types of spring cable reeling drums are available in

3 types viz monospiral, standard lay and random lay.

ORTON have a complete range of motor driven torque controller cable

reeling drums. The reels shown in this catalogue are direct reeling

units where the cable compartment is mounted directly on the torque

controller. For those applications where the length and weight of the

cable is in excess of the design capability of the direct reeling units,

we have the indirect driven torque controller reels. With these reels

the torque controller unit powers the reel compartment through a

suitably selected transmission system. These types of cable reels are a

reliable, low cost solution for reeling long lengths of cable. These

drums are available for a complete range of cable lengths from 30 to 500

meters, for voltage up to 11000 V. These spring operated cable reeling

drums are easily installed, have an absolute minimum maintenance

requirement and are virtually unaffected by extremes of temperature and

environment. These types of spring cable reeling drums are available in

3 types viz monospiral, standard lay and random lay.

Advantages

Working

Principle

Working

Principle

Torque controller type cable reel are driven by a substantially constant speed motive power unit. In its standard form, the reel is designed to be powered by a totally enclosed fan cooled electric motor. The most popular choice is for motors working form a 3 phase supply but single phase or DC motors may also be used provided they have performance characteristic as in accordance with the torque controller data.

The motive power unit drives the cable reel through an irreversible worm an wheel transmission which is totally enclosed and lubricated for life. The reduction ratio of this worm and wheel transmission is normally 50:1 and the rotational speed of the transmission out put spindle is adjusted by selection of the motive power speed. In all cases the selected rotational speed of this output spindle is in excess of that required for the cable reel.

The speed differential between the transmission output spindle and the cable reel is accommodated by the torque controller using a friction pad as the slipping interface.

The irreversible worm and wheel transmission and the stable torque characteristics of the torque controller permit successful cable reeling on the basis of energizing the motor for cable recovery. The benefits of energizing the reel motor for cable recovery only, are increased lining life and extended intervals between torque correction adjustments.

TC Payout Sensor Operation

The basic function of the payout sensor is to detect the rotation of the reel ensuring that the reel motor is energised during cable recovery and de-energised during cable payout. A limit switch is operated byaswivelingarm which is rotated by means of a cam fitted to the reel spindle. When the reel revolves in a payout condition the arm is moved until it opens the contacts in the limit switch de-energising the reel motor. In the reel-in condition the arm is rotated away from the limit switch making the contacts energising the reel motor.

Since the payout sensor cannot anticipate the direction of rotation of the reel under start conditions, the reel motor is always energised for 30 seconds by the incorporation of a timer in the control circuit which by passes the payout sensor contacts. This timer allows sufficient time for the sensor to detect whether the machine is moving towards the cable anchor position or away from it so ensuring that the reel motor is either energised or de-energised.

Standard reels are supplied for the cable fed in the clockwise direction, when viewed from the slipring side. The same can be provided for anticlockwise feed of cable also. These reels are extremely simple to mount, and can be mounted on the structure with the help of a supporting flange - If no suitable structure is available, then Unbalanced Vibrator Motor a bracket can be connected to the flange and this can be fixed to the floor or tray etc.

The springs used in these reels are manufactured from the highest quality materials and are of clock spring type. A wide range of characteristics can be obtained by assembling these springs singly or in series or in parallel.

All the power sliprings are designed for 600V AC operating voltage.

Spring operated cable reeling drums can also be supplied with geared rotary limit Switch arrangement.

ORTON have a complete range of motor driven torque controller cable

reeling drums. The reels shown in this catalogue are direct reeling

units where the cable compartment is mounted directly on the torque

controller. For those applications where the length and weight of the

cable is in excess of the design capability of the direct reeling units,

we have the indirect driven torque controller reels. With these reels

the torque controller unit powers the reel compartment through a

suitably selected transmission system. These types of cable reels are a

reliable, low cost solution for reeling long lengths of cable. These

drums are available for a complete range of cable lengths from 30 to 500

meters, for voltage up to 11000 V. These spring operated cable reeling

drums are easily installed, have an absolute minimum maintenance

requirement and are virtually unaffected by extremes of temperature and

environment. These types of spring cable reeling drums are available in

3 types viz monospiral, standard lay and random lay.

ORTON have a complete range of motor driven torque controller cable

reeling drums. The reels shown in this catalogue are direct reeling

units where the cable compartment is mounted directly on the torque

controller. For those applications where the length and weight of the

cable is in excess of the design capability of the direct reeling units,

we have the indirect driven torque controller reels. With these reels

the torque controller unit powers the reel compartment through a

suitably selected transmission system. These types of cable reels are a

reliable, low cost solution for reeling long lengths of cable. These

drums are available for a complete range of cable lengths from 30 to 500

meters, for voltage up to 11000 V. These spring operated cable reeling

drums are easily installed, have an absolute minimum maintenance

requirement and are virtually unaffected by extremes of temperature and

environment. These types of spring cable reeling drums are available in

3 types viz monospiral, standard lay and random lay. Advantages

- Uses standard AC or DC motor as prime mover.

- This design reduces tensions in the reeled cable substantially as against other form of drive.

- Lubricated for life gearbox. o Range of drive units to suit various sizes and length of cable to be reeled.

- Reduced overall size as compared with conventional motor.

- No chain drives, hence reduced maintenance.

- Selected reel will cover wide range of cable length & sizes.

- No additional brake required

- Combinations of core sizes and quantities can be readily accommodated, in standard size of housing.

Working

Principle

Working

PrincipleTorque controller type cable reel are driven by a substantially constant speed motive power unit. In its standard form, the reel is designed to be powered by a totally enclosed fan cooled electric motor. The most popular choice is for motors working form a 3 phase supply but single phase or DC motors may also be used provided they have performance characteristic as in accordance with the torque controller data.

The motive power unit drives the cable reel through an irreversible worm an wheel transmission which is totally enclosed and lubricated for life. The reduction ratio of this worm and wheel transmission is normally 50:1 and the rotational speed of the transmission out put spindle is adjusted by selection of the motive power speed. In all cases the selected rotational speed of this output spindle is in excess of that required for the cable reel.

The speed differential between the transmission output spindle and the cable reel is accommodated by the torque controller using a friction pad as the slipping interface.

The irreversible worm and wheel transmission and the stable torque characteristics of the torque controller permit successful cable reeling on the basis of energizing the motor for cable recovery. The benefits of energizing the reel motor for cable recovery only, are increased lining life and extended intervals between torque correction adjustments.

TC Payout Sensor Operation

The basic function of the payout sensor is to detect the rotation of the reel ensuring that the reel motor is energised during cable recovery and de-energised during cable payout. A limit switch is operated byaswivelingarm which is rotated by means of a cam fitted to the reel spindle. When the reel revolves in a payout condition the arm is moved until it opens the contacts in the limit switch de-energising the reel motor. In the reel-in condition the arm is rotated away from the limit switch making the contacts energising the reel motor.

Since the payout sensor cannot anticipate the direction of rotation of the reel under start conditions, the reel motor is always energised for 30 seconds by the incorporation of a timer in the control circuit which by passes the payout sensor contacts. This timer allows sufficient time for the sensor to detect whether the machine is moving towards the cable anchor position or away from it so ensuring that the reel motor is either energised or de-energised.

Spring Operated Cable Reeling Drums

Motorised Cable Reeling Drums

The Motorised Cable Reeling Drums, offered by

us are supports various cables reeling applications. Powered with

springs and supported by automatic rewind feature, these reeling drums

serves as simple source of power supply to machines like cranes and

hoists. The reel drums, available with us will cover wide range of cable

length & sizes.

Specifications :-

Color : Red, Yellow

Diameter : >500 mm

Max Cable Length : >25 m

These are available in three variations:

Owing to their design, these drums help in reducing tensions

in the reeled cable substantially as against other form of drive. Other,

fruitful features includes, improving upon the lining life and they also

extend intervals between torque correction adjustments.- Mono-spiral

- Standard lay

- Random lay

Specifications :-

Color : Red, Yellow

Diameter : >500 mm

Max Cable Length : >25 m

Stall Torque Motor Operated Cable Reeling Drums

These types of cable reefing drums are

normally used for cables of size 4c x 25 sq mm (max) and cable lengths

upto 20 mtrs. However these drums can be used even upto 150 mtrs if the

cable diameter is small (say.4cx2.5sqmm).

In case of stall torque Motorised cable reeling drum the stall torque motor remains energized in both winding and unwinding operation of cable. In case you want to save power during long stoppages of machine, then a contractor and timer circuit can be installed in your panel. However, this is only an optional feature and is not a mandatory requirement. Since the stall torque motors are continuously rated, there will be no problem even in the motor remains continuously oh during both winding and unwinding direction.

In case of stall torque Motorised cable reeling drum the stall torque motor remains energized in both winding and unwinding operation of cable. In case you want to save power during long stoppages of machine, then a contractor and timer circuit can be installed in your panel. However, this is only an optional feature and is not a mandatory requirement. Since the stall torque motors are continuously rated, there will be no problem even in the motor remains continuously oh during both winding and unwinding direction.

Sprocket Driven Cable Reeling Drum

These types of cable reeling drums are used to

avoid; tension on the cable. However, a drive mechanism is required to

drive the cable reeling, which is not required in case of spring

operated or motorised CRD's.

These types of cable reeling drums are recommended for single layer winding of cables.

Applications

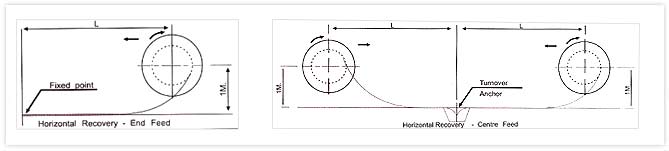

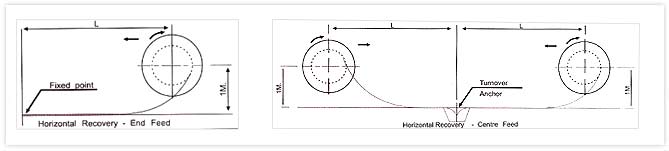

HORIZONTAL RECOVERY:

This arrangement can be used in two applications i.e., end and centre feed. In the end feed type, the drum is mounted on the moving machine and the reel recovers the cable laid on the ground. Here the machine travel is equal to the capacity of the reel. In the centre feed type, the machine travels on both sides of the fixed point, where a turnover anchor is installed. This arrangement provides travel equal to twice the capacity of the reel.

VERTICAL RECOVERY:

In this type also the reel is machine mounted and the biggest advantage of this type is that it does not have to pull the weight of the cable since, in this case the complete weight of the cable is felt at the fixed point.

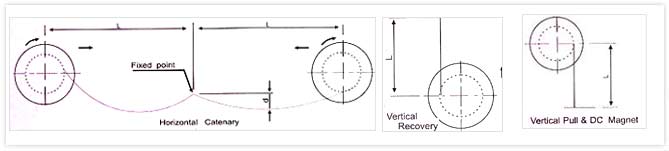

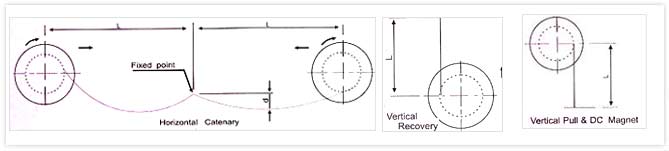

HORIZONTAL CATENARY:

In this type of arrangement. the cable is not laid on the ground but is suspended in the air due to the tension of the spring.

VERTICAL PULL:

Here the reel is mounted on a fixed structure and has' to overcome the weight of the hose. The length of travel is equivalent to the capacity of the reel.

These types of cable reeling drums are recommended for single layer winding of cables.

Applications

HORIZONTAL RECOVERY:

This arrangement can be used in two applications i.e., end and centre feed. In the end feed type, the drum is mounted on the moving machine and the reel recovers the cable laid on the ground. Here the machine travel is equal to the capacity of the reel. In the centre feed type, the machine travels on both sides of the fixed point, where a turnover anchor is installed. This arrangement provides travel equal to twice the capacity of the reel.

VERTICAL RECOVERY:

In this type also the reel is machine mounted and the biggest advantage of this type is that it does not have to pull the weight of the cable since, in this case the complete weight of the cable is felt at the fixed point.

HORIZONTAL CATENARY:

In this type of arrangement. the cable is not laid on the ground but is suspended in the air due to the tension of the spring.

VERTICAL PULL:

Here the reel is mounted on a fixed structure and has' to overcome the weight of the hose. The length of travel is equivalent to the capacity of the reel.

Thrustor & Thrustor Operated Brakes

Features :

- Self contained unit, therefore needs no external components accessories.

- Constant thrust is achieved at all positions of working stroke.

- Smooth linear motion.

- Extremely compact & very little maintenance required.

- Lower power inputs & low heat generation.

- Permissible up to 720 switching per hour operations.

- Thrustors are totally enclosed with IP-55 degree protection

Gantry Crane

Features :

- Self contained unit, therefore needs no external components accessories.

- Constant thrust is achieved at all positions of working stroke.

- Smooth linear motion.

- Extremely compact & very little maintenance required.

- Lower power inputs & low heat generation.

- Permissible up to 720 switching per hour operations.

- Thrustors are totally enclosed with IP-55 degree protection

Goliath Crane

We are the Manufacturer and exporter of

Goliath Crane

Features :

Features :

- Lower power inputs & low heat generation.

- Permissible up to 720 switching per hour operations.

HOT Cranes

We are the Manufacturer and exporter of HOT

Cranes

Features :

Features :

- Constant thrust is achieved at all positions of working stroke.

- Smooth linear motion.

Crane Accessories

We are the Manufacturer and exporter of Crane

Accessories

Features :

Features :

- Lower power inputs & low heat generation.

- Permissible up to 720 switching per hour operations.

Crane Accessories

We are the Manufacturer and exporter of Crane

Accessories

Features :

Features :

- Lower power inputs & low heat generation.

- Permissible up to 720 switching per hour operations.

Gantry Crane Motorised Cable Reeling Drum

With our rich industry experience, we are Manufacturer and Service Provider of a wide assortment of inventively designed Automation & Control Systems, Electro Robotech and Automation Products. The offered range is precisely manufactured using optimum quality raw material and innovative technology. These products are known for their distinguished features like perfect finish, sturdy design, accurate dimension and durability. Our esteemed clients can avail the offered product from us in various specifications from us at market leading prices.